Cat C7 Oil Pressure Sensor Location (Helpful Guide)

With all the new diesel regulations and standards finding the small parts can get tough. They are usually placed in out-of-the-way spots and are often hard to view as other larger parts block your view. Sometimes you need a mirror to see them.

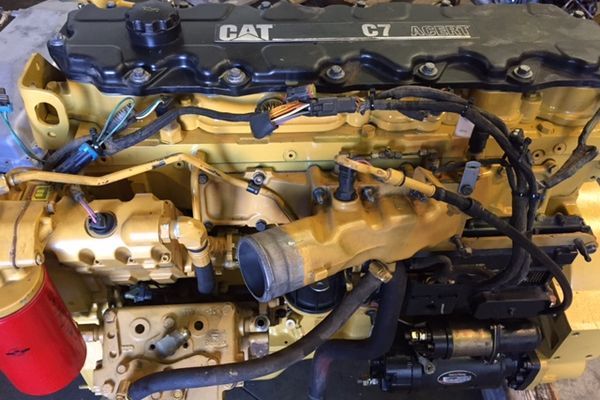

The oil pressure sensor is located near the bottom of the block but above the oil pan. It is hard to tell the exact location with a diagram but a photo puts its location under and next two hoses on the driver's side of the block. You may need more than a mirror to find it.

To learn more about the location of this part just continue to read our article. It has the information you want so you can find this part and replace it easily. It is in the best spot to monitor oil pressure but not in the best spot for mechanics to access.

Caterpillar c7 Oil Pressure Sensor Location

The following photo was taken from an RV discussion forum. The poster will be linked to underneath the image and it is with a grateful heart that we place it here. As they say, a picture is worth a 1000 words of explanation or description.

The red circle is the oil pressure sensor and you can see how difficult it is to access. The image was taken from this website- https://www.irv2.com/forums/f115/oil-pressure-sensor-location-556269.html

This image corresponds with the diagram we are about to post. The sensor will be #8 in the diagram:

** diagram is from this website- http://www.catengine.info/workshop/c7/c7-industrial-engine-operation-and-maintenance-manual-sensors-and-electrical-components.html

The diagram seems to have placed the sensor a little lower than the photo does but them we are not expecting precision with the diagram.

Cat C7 Sensor Locations

The photo and the diagram provide you with the best views of this sensor even though the location may be a bit off between the two. But if you look on the driver’s side of the block about halfway down and you should find it.

We cannot guarantee that access to your oil pressure sensor will be easy or that you won’t need a mirror to find it. What we can guarantee is that you may have to remove other parts to replace this sensor.

Modern engines have become mechanics’ nightmares with all of the additional parts used to create these top motors. #5 in the diagram is the engine oil temperature sensor but you may not be able to see it in the photograph.

The other emissions and vital parts of a diesel motor are in the way of a smooth repair. If you go to the link for the diagram you will see what the other numbers are pointing to.

One thing is for sure, if you are not working on your Cat C7 yourself, you may be padding the labor bill when you have that sensor replaced or repaired. Engines just are not like they were in the old days.

What Happens When The Oil Pressure Sensor Fails?

One of the good things about modern engines is that they have a part that monitors all the other parts or sensors. In this case, there is an ECM device watching over the sensors and if anything happens to the oil pressure sensor, then you can expect the following to take place:

The ECM will detect the problem and illuminate the dashboard diagnostic light. Once illuminated you have been warned that this part is failing or has failed on you.

When the light is on you know that all oil pressure strategies have been disabled. The good news is that if this part fails, you will not lose any horsepower or face a derate.

The engine should work as usual but you should get the sensor changed as soon as possible. So it is not a serious problem but it may lead to a serious problem if it is not taken care of when you get a chance to work on your engine.

As all of our past recommendations have said, if you are not mechanically inclined or at an age where working on engines is not so healthy for you, then go to a good mechanic to have the work done.

How To Test The Oil Pressure Sensor

There is a mechanical gauge that you can buy and hook up to see if this sensor is working right or not. One of these gauges is the Datcon Oil Pressure Sender 06555-7353 and it is a one wire set up that connects to the same spot as your oil pressure sensor.

If you get a higher-than-normal reading on this gauge, then you know that the sensor is failing or has failed on you. The normal reading is around 31 PSI. The normal pressure range for oil in the C7 is 0 to 100 psi.

Higher or lower than 32 indicates you have a slight problem depending on where the needle falls in that range. You should have some leeway for the normal psi operating level and read your manual to see what that leeway is.

You can probably get the gauge or other models from the various auto parts outlets or engine parts and accessories stores in your city. We have not checked the price on that gauge but it should be affordable.

It is a handy tool to have around as monitoring your oil pressure is essential to performance as well as fuel efficiency.

Oil Pressure Warning Light

There are two meanings you should be aware of when you see that oil pressure light illuminated. The first meaning is that you only have low oil pressure. The set point is determined by the engine speed.

The fault will be activated but not logged unless the engine has been running for 15 seconds or more. This is the stage where you will not face a derate or loss of HP.

The second definition is called a very low oil pressure reading and it is something you should be concerned about. The set point for this level is also dependent on engine speed but far worse actions will be taken if you hit this level.

The derate may occur depending on the mood of the ECM. If it does select the derate expect to lose both HP and power. This is why you want to monitor the oil pressure as you drive.

But you should be able to avoid the derate if you act fast when the sensor says your oil pressure is only low. The engine oil temperature sensor is a far worse part to have to fail on you and that is something you should watch as well.

The Engine Oil Temperature Sensor

It is important that we spend a few words on this little part as well. It is number 5 on the diagram and in an elevated position in comparison to the oil pressure sensor.

Its job is to monitor the oil temperature while the engine is operating and your range of operation is between -40 to +258 degrees F or -40 to +120 degrees C. You just have to make sure the oil temperature does not get too hot while you are driving.

The fix for either sensor if they are failing or have failed on you is the replacement of one, the other, or both sensors. You can replace both if you feel it is time to do so. That way you can avoid a problem later on down the road.

Cat C7 HEUI Pump Problems

If your C7 has the Hydraulic actuated electronically controlled unit injection (HEUI) installed on it, then you may be aware that there are some common problems many C7 owners will experience.

The system is operated electronically but it needs high oil pressure to make the injection system work. The high-pressure oil pump is the main part that creates the high oil pressure and it is connected to the HEUI system.

Unfortunately, this system can have its operation interrupted by the following common problems:

1. Filters- there are a lot of them on this engine and as you know these filters stop contaminants as well as dirt and dust from entering the engine’s systems. These filters may seem like an unimportant part of the motor but when they get clogged they can influence engine performance for the worse.

Make sure to keep the filters changed so that your C7 can operate to its fullest potential.

2. Valves- Caterpillar uses 2 different types of valves on this engine model and if they go bad, and they can fail on you, then you are looking at some hefty repair bills.

When the valves get damaged the pumps begin to malfunction. What complicates the repair is that the engine must support the new valves or you may not get the engine to work.

Contact a CAT dealer or the company itself for the right valves. 3rd party valves may not be up to Cat’s specs so be careful if you choose to go that route.

3. Engine oil- there are many problems associated with this lubricant. It can get too low, dry out, or there may be a leak somewhere. When there is a problem with the oil, there will be a problem with a variety of parts in the engine.

When you see that oil light illuminate on your dash, make sure you have enough oil in the crankcase. Just do regular and proper maintenance on the oil to protect the pumps and other parts.

You should not have any trouble with the engine if you keep to the recommended oil change schedule.

4. Engine overheating- this has been a common complaint as many owners have complained that their C7 overheats at around 200 degrees F or just above that temperature point. However, the cooling fan is not set to turn on till the engine temperature reaches 235 degrees F.

Unless you can change the temperature setting for the cooling fan, you may have to drive no faster than 1100 RPM when you are going uphill. This is one of the bigger flaws in this top diesel engine. Talk to a good mechanic about fixing this problem.

5. Advanced Combustion Emissions Reduction Technology or ACERT- One of the advanced technologies that have caused a lot of embarrassment for Caterpillar. It was not their best upgrade.

Clogged diesel filters and turbocharger inlets were the main sources of trouble for this technology.

C7 Engine Rebuilding Costs

The C7 is known for being able to last for 500,000 miles but this is not always the reality. Some owners have seen this engine fail far sooner than that 500,000-mile mark. They are lucky to get 10,000 to 50,000 miles out of the engine before a failure occurs.

When this engine fails you are looking at thousands of dollars in costs to rebuild it. The reason the expense is so high is that this engine needs a certain level of parts that cost even more money.

If you can’t get high-quality fluids or components, then you may be asking for another repair bill a few years down the road. This is why there have been warnings out there to not use 3rd party parts when you need to repair different components.

They are just not up to the task. Part of the problems for this failure can be the injector seals or the compression rings. When both parts go bad your C7 should use a lot of oil.

Doing regular maintenance and inspections on this motor is one key to a long lifespan.

Some Final Words

Finding the oil pressure sensor is going to be most of the battle. To replace it once you find it is easy. But do a test on it with a gauge to make sure that it is the oil pressure sensor that is failing on you.

It is a lot of work to take it out and put the new one in. Make sure you are ready for the time it will take to fix.