Splicing 10 Gauge Wire (How to Splice 10 Gauge Stranded Wire)

When you are looking at doing this task, there are a lot of electrical DIY RVers who can provide you with great advice and techniques. You just have to pick the one that will work the best in your RV situation

One option you can use would be to solder the wires together and use a heat shrink covering. In fact, you may need 2 heat shrink tubing to make the connection last a long time.

To learn more about this topic, just continue to read our article. It has the information you want to know about so you can do this job yourself and save a little money. No sense paying the high dealer costs for something this simple.

Can You Splice 10 Gauge Wire?

Yes, you can and the experts agree that you need to splice it with more than 10 gauge wire. It is not recommended to splice it with 12 or other gauge wire. The reason for this is that 10-gauge wire is rated for 30 amps and 12 gauge is rated for 20 amps.

Even if you are connecting more than 2 wires together, you need to stay with the same gauge. Keeping the wires connected will be your main issue.

Best Way To Splice 10 Gauge Wire

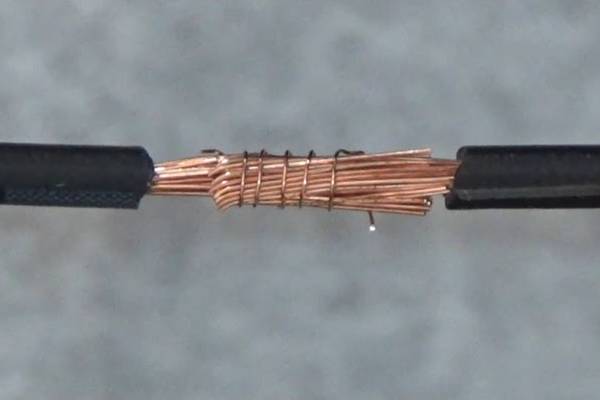

There are different methods you can use. But just using electrical tape is not on the list nor is it your best option. The best option would be to solder the wires together and then put heat shrink tubing over the splice.

Another suggestion would be to use wire connectors and then cover those connections with electrical tape. This keeps the connectors from vibrating off the splice.

A third option would be to use 2 ring terminals, a bolt, and then heat shrink tubing. The bolt goes through the middle of the rings and wire connection.

How To Splice 10 Gauge Stranded Wire

This will depend on what you are connecting. One option would be to use a J box and then a separate pigtail for different outlets. In this method, you would need to use the right-sized wire nuts.

Also, you would need to make sure the J box is large enough. 10-gauge wire does not like being bent in small places.

10 Gauge Wire Junction Box

These items are on sale wherever electrical supp[lies are sold. That would include the big home improvement stores, not the usual big box retailers. The prices are fairly reasonable for these junction boxes.

One outlet has them on sale for about $30. But shop around as you may find a good box at a lower price. If you need advice, it is best to go to true electrical supply outlets as those people are generally the experts on wiring and connecting wires in a J box.

Connecting 10 Gauge Wire

Soldering is said to be the best option as it makes a solid connection and then you can secure that connection with either electrical tape or a heat shrink connector.

However, if you do not know how to solder, you will need to use 8 gauge wire nuts or connectors. This will be the size that will accommodate the large wires. Try to avoid using scotch locks or quick-connect connectors as they are not reliable nor are they waterproof.

10 Gauge Wire Quick Connectors

You can find these on Amazon and that marketplace has a wide variety of them for you to choose from. Depending on the style you need, they are all priced under $20 so they are affordable.

Or you can go to a true electrical supply and get the best information on these connectors and if they truly are waterproof and reliable. They can be helpful if used in the right circumstances.

But it is always better to go with a standard method of connection. That way you are assured of a good connection.

10 Gauge Wire Terminals

These are interesting little connectors. They come with a ring in the terminal which can be connected by a nut and a bolt. Plus, many options already come with the heat shrink tubing so you can easily make your connection in a few minutes.

Not all will be in this design as some are made with a vinyl cover and a crimp-based connecting head. If your crimping tool is strong enough these should not be any problem either.

10 Gauge Wire Nuts

Everyone should know or at least recognize this vital electrical part. To use them, you just twist the two wire ends together and then twist the nut over that connection.

The key to using them is to make sure the bare wire is not longer than the nut. These nuts are simple to use and make a great connection. But they have the reputation of vibrating off when in a moving vehicle.

What Size Wire Nut For 2 10 Gauge Wire?

You would want to go to 8 gauge size as that will provide the room you need to make the connection and keep it together. While most people may want to use 10-gauge, which is possible, those smaller nuts may not always have the room you need to work with.

10-gauge wires do not like being bent in tiny places. But you can always double-check with the pros at an electrical supply outlet.

Some Final Words

Making the right electrical connections depends on the tools you use. The wires are going to be thicker than you may normally be used to working with. But with the right junction box, some soldering, or connectors, you can get the job done right.

That is the most important aspect of electrical work. Getting the job done right spares you a lot of problems and keeps you protected in case the insurance company has doubts about paying for any damages. Get the right parts to be safe.