Freightliner Air Suspension System Diagram (Parts Breakdown)

One of the things about the truck and auto industry is that the manufacturers are always making changes. One air suspension system diagram may be a bit different from another one made a year or two later. There will never be a one size fits all diagram.

The problem with posting diagrams for different systems, whether they be electrical, air suspension, or even plumbing is that they are not always identical. Some may look similar but there will be minute changes made from one year to the next.

To see and learn more about this system, just continue to read our article. It has the information you want to know about so you can handle any repairs if you want to. Take a few minutes to see how this important information helps you.

Freightliner Air Suspension System Diagram

As we have said already, the diagrams that we post here may work for your specific RV or truck model or they may not. That is because RV, auto, and truck makers are always upgrading designs to their different systems and nothing is identical from year to year.

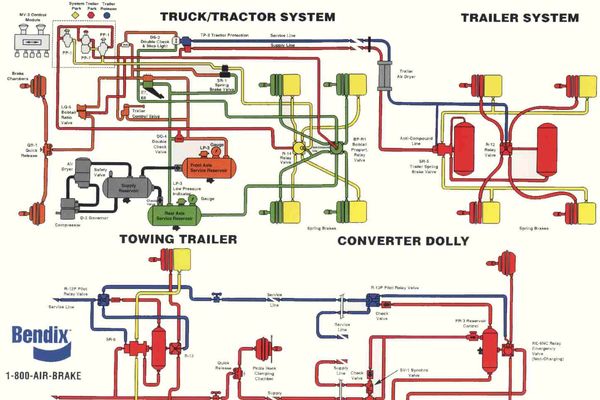

This image may be a little fuzzy but here is a link to see it in a different format. We have another link to a different chassis air lines that may also be of some help to you. Click here to see the diagram.

The second link is for an 03 chassis but it is almost identical with the 04 models. The keyword is ‘almost’. There will be some differences between the two model years.

Freightliner Rear Suspension Diagram

Here is an exploded diagram for the suspension. What is missing from the diagram will be the corresponding names of tall the parts for each number on the diagram.

This diagram is labeled as the rear suspension system for a Freightliner chassis. There are no other specifics attached to this diagram.

Freightliner Airliner Suspension Parts Breakdown

This link takes you to an NHTSA gov website that should provide you with a parts breakdown. It has the different parts numbers in its 5-page length. Those part numbers are for the 5-piece welded, the 5-piece bolted, and the 6-piece cross member suspension systems.

Also at that link, you will find some very clear and unexploded diagrams to help you make your repairs. If you are doing a cross member replacement, the last 2 pages hold the 12-step process to get it done right.

When you read that document, there are no warranties or guarantees applied. It is an information only document. We will also caution you about the application of this information.

It may not be helpful for older suspension systems and you should talk to a qualified Freightliner mechanic or a Freightliner dealer to get specific information for your vehicle’s model year.

There are other diagrams on the internet but most do not put a model or model year for these alternative diagrams.

Common Freightliner Airliner Suspension Issues

1. Air Bag Leakage- because of the constant stress put on these components, you may either have a leak or a large blowout of the air bags. Replacement will be the only cure for this problem.

Also, check them regularly because the wear and tear on these air bags shorten their lifespan considerably.

2. Rough ride issue- this may happen in the front suspension system. At least that is what most of the reports that have been made have indicated. The factory leaf set up is considered to be the source for this problem.

The fix will be retrofitting two full-length leaf springs set up in the front suspension.

3. Lateral Torque Rod Bush Failure- rubber bushings are used to attach the rear lateral torque rods to the drive axles. Both the bushings and the torque rods can and will wear out.

Keep an eye on them and replace them when you see they are getting too worn out. The rubber bushings can be replaced with poly bushings. These poly bushings should extend the life of the system a little bit.

4. Rear axle vibration- this can happen between the speeds of 45 to 75 miles per hour. This vibration can cause cupping and increased uneven wear on the rear tires.

The source of the problem seems to be in the driveshaft support bearing. It is a design flaw. One solution is to modify the angle of the driveshaft. Another is to extend the length of the load sensing lever by ⅜ inch, which causes the ride height to increase by ¾ inch.

Where To Find Airline Suspension Parts

One of the best places to go would be Stengel Bros. Their parts store has popped up in a number of searches we have already made. Anything Truck.com is another good location to find the parts you need for this suspension system.

Not to be outdone, Vander Haag offers new and used parts for Freightliner suspension systems. Their used suspensions go back to 1990 and are on track for next year’s models as well. Expect to pay between $550 and just over $1000 for the used suspension you need at this outlet.

There are quite a few outlets that are selling parts for this suspension system. A quick internet search will turn up more than a few that are near you. Don’t forget to comb the different junk yards.

They should have some quality used parts at a decent price as well.

Some Additional Words

These diagrams should get you started on the right track for your repair needs. As we have stated throughout this article, your specific Freightliner chassis and suspension may differ slightly from what these diagrams say.

If you are not sure about the ones you find online, talk to a Freightliner repair shop, a dealer of the company itself to see if they can supply you with one that fits your RV or truck’s model year. Slight differences in designs and size do make a difference.