Slide Out Motor Repair: Finding a Schwintek Motor Replacement

When your RV or trailer seems to be on the small side, it is always nice to have a slide-out or two to enhance your living space. Slide-outs make RV living better except when the motors do not work or you have to do some other type of repair.

Finding a Schwintek Motor Replacement does not seem to be a difficult task. A quick search produced several options at Amazon that will work or be made by Lippert themselves. Or you can call the company and see if they can send you the right part. The cost is going to be the biggest hurdle to overcome no matter what.

To learn more about finding a replacement Schwintek motor, just continue to read our article. It has that information and a lot more. Take a few minutes to see how this data can help you out of difficult situations.

Schwintek Slide Motor Not Working

If your slide-out motor is not working, the best fix is a replacement motor. But it is not the only fix you can do. The first thing to do is check the harness and see if there is a proper connection between it and the motor.

The next step would be to look for kinks or any possible damage. If there is no damage, you may have to go to the last fix, which is to replace the motor. Before you do that make sure to test the connection with an ohmmeter or a test harness to make sure the motor is bad.

The Schwintek troubleshooting guide will help you identify what the error codes mean and should help you fix the problem before you replace the motor.

Slide-out Motor Repair

This will depend on the type of problem you have. According to their repair guide, if the controller’s LED light lights up but there are no error codes you need to go to page 9 of the manual to find the right instructions.

If those LEDs do not light up and there are no error codes then you have to check the 12VDC in the controller, the switch connection, and then the battery for the 12VDC. Then if you get error codes, the label on the controller will have the meanings to those codes. Then just follow the repair instructions.

Sometimes the problem can be as simple as the seals getting stuck in the rollers. The seals should not be binding at any time.

Schwintek Slide Motor Location

The motors seem to be in the vertical beams on the slide. There is a small screw that holds the cover in place which needs to be removed to give you access to the motor. The motor is just above where the gears interact with each other and once you get the retention screw out you should have good access.

However, some people have reported that the access space can be as small as 3 inches. So you need to be prepared for working in tight spots. There is only one screw holding the cover and there may not be a screw holding the motor still.

If there is, it may be a Robertson, a Phillips, or a flat head depending on which one the company decides to use.

Common Schwintek Slide Motor Problems

If you have an early model of this motor, your system may be filled with plastic gears that do not hold up over time. This will be one of the issues you may face on a regular basis.

When you look at the label you will find that the error codes all have to do with electrical issues. That would be your next common problem. There are about 7 error codes for these issues. The codes will also tell you which motor has the problem.

Other common problems will be synchronizing the motors. Once your slide is in or out, you should continue to hold the button for a couple of seconds so that the unit can reach the end of its cycle. This keeps everything in sync and provides a smooth operation.

Finally, if you do not level your RV properly, the chassis can twist and cause you a lot of problems.

Schwintek Motor Retention Screw

There is only one of these for each motor that you have to worry about. They are located at the top of the cover and should only take either a Robertson or Phillips head screwdriver to remove them.

The key difficulty in this removal process is having enough room to maneuver the screwdriver. You may have to go to a stumpy size to make sure you have that room. What sets this screw apart is its color.

The retention screw should be a silver color while the rest of the screws nearby will be black. Also, you should pull back the bulb seal to gain access to the retention screw. It is a simple setup made difficult by the extra items thrown in your way.

Schwintek Motor Short Circuit

If you have a short circuit, the green LED should blink once for motor #1 and twice for motor #2. Then the red LED should blink between 2 and 9 times depending on the problem. Just make sure to count accurately when you see the blinking lights.

To indicate a short in the system, the green LED will indicate which motor, then after that, or at the same time the red LED light will blink 6 times. From that point, you have to figure out exactly where the short is in the system. But at least you know the problem and which motor it is affecting.

When you see this signal, the manual says to consult the manual or tech services. It also says to email their support department to get help. At no time do the manuals we checked say you can fix this yourself.

Schwintek Slide Motor Wiring Diagram

The repair manuals that we consulted did not have a wiring diagram included in their formats. This link will get you to one diagram that may or may not apply to your slide-out situation but it is a start.

The next link will have a picture of a wiring diagram on page 19 of the LCI manual. If this link does not bring you right to the diagram, just scroll down until you see it. You cannot miss it as the page is labeled wire diagram.

The latter diagram will show both motors so that you will have no confusion. If you do not like working around these parts or in tight quarters, it will be best to get a professional to handle the work for you.

Schwintek Parts Breakdown

According to the wiring diagram, you are going to have 2 motors with 2 harnesses attached. From the switch, there are modified power switch wires and these are color-coded to make sure you can replace the right ones.

At the controller, there will be a switch junction and a power junction. The former is on the bottom and the latter is on the side nearest the second motor. Then there is a built-in circuit protection part that helps make sure there are no overloads to the system that will harm the motors.

Any one of those parts can fail and if there is an interior part that breaks down, it looks like replacement is the only option on all of these components. Study the color-coding to make sure you understand which colored wire goes where.

Finding a Schwintek Motor Replacement

As we noted earlier, Amazon has Lippert slide-out motors available. Their prices range between $60 and $230. E-trailer has some in stock and you should contact that website to see what the price is and for which model it goes.

There are a number of outlets that you can find on the internet. The question will be how close are they to you. You can contact the company directly and see if they sell to customers. Not all companies do but it is worth checking out.

Check your local listings to see if there is an RV parts and accessory outlet near you. They would most likely have the motor in stock or should be able to order one for you.

When you go to find the part, make sure you have your RV or trailer model, motor model number, and serial number. This will facilitate the search and speed up the process.

How To Test a Schwintek Motor

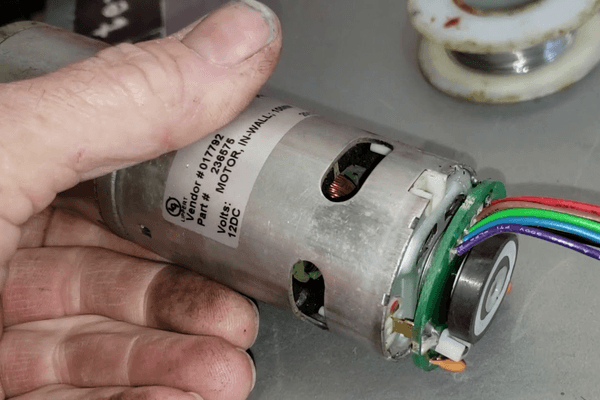

If at all possible you should use your multimeter to do the testing. Lippert or Schwintek motors are designed to work with as few as 8 volts of electricity. But this is not an advisable level to have in your system.

When the slide is moving slowly, use the meter and check to see how many volts are running through the system. If the meter registers less than 11 volts, then you should place the battery on a charger and boost its power back up.

Another check you can do is the LED lights. If they do not light up you should unplug and then plug in again the power to those lights. If they do not light up after this, then there should be a problem with the switch. Or there is a problem with the wiring.

How To Replace a Schwintek Motor

Buy your new motor first. You can do this at any shop you like to purchase your RV parts from. The key to replacing the motor is to be careful as the parts can be delicate and easy to break.

In some models, this process only takes about 5 minutes to do as these motors are not in very complicated or crowded areas of your RV. Your biggest hassle will be the amount of space you will have to work with.

Then just be patient as there is only one screw to remove and the motor should come out fairly easily for you.

How To Remove a Schwintek Motor

Once you have your new motor, just follow the upcoming steps:

Step 1: Pull the bulb seal off to reveal the retention screw. Then unscrew this screw.

Step 2: Lift up the motor but do this carefully. If you need to you can pry the motor up but this often results in bringing the bushing with the motor. If that happens just push the bushing back down. You do not want to lift that bushing too high as it can separate from the bearing block.

Step 3: Plug the harness into the new motor but be careful here as well. Lippert redesigned the new motors so pay close attention to how the harness plugs into the old motor.

Step 4: Put the new motor in place and screw the retention screw in and replace the bulb seal.

Schwintek Slide Motor Lubrication

There are two key spots where you need to apply lubricant. One spot is called the gib and it is the spot where the bearing block rests. Since there is contact there, just give the gib a couple of sprays and it should be lubricated. Do both gibs.

The second part that needs lubrication is the coupler and it is inside the bearing block. This is a round part and it needs to be well coated with lubricant but do not overdo it. To get to the coupler you need to pull the dust flap back and go in from the top.

Some Final Words

In most cases, the Schwintek motor is a very precise machine. Just make sure to not stop the slide-out movement until the cycle has finished. This will keep the motors in sync and function normally.

When you have problems, make sure to check with a tech first before doing any repairs. Watch your warranty as well as you do not want to void it out.